At AquaClarion, our water treatment technology team knows that understanding the core component—the reverse osmosis membrane—is crucial when choosing an RO system. This article explains the technical principles behind how the RO membrane acts as the final and most critical barrier for your home’s drinking water safety.

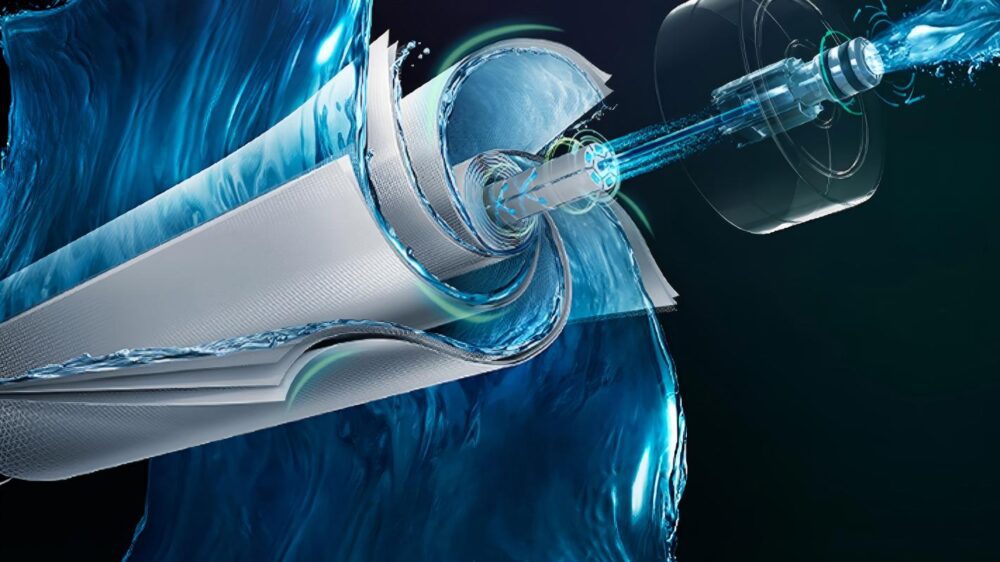

1. The Core of the RO Membrane: A Multi-Layered Composite Structure

Each layer in the Thin-Film Composite (TFC) RO membranes used by AquaClarion has a vital role:

- Polyester Non-Woven Support Layer: Acts like a building’s foundation, providing mechanical strength to ensure membrane stability under pressure.

- Polysulfone Porous Intermediate Layer: A sponge-like structure with high porosity that creates pre-formed channels for water molecules to pass through.

- Polyamide Active Separation Layer: Only about 0.2 microns thick, this layer contains nano-sized pores and serves as the true “intelligent checkpoint” for selective separation.

This structure ensures durability and high efficiency under high water pressure, forming the basis for the long-lasting filtration performance of AquaClarion RO systems.

2. Ultimate Filtration Precision: What Does 0.0001 Micron Mean?

The pore size of an RO membrane is approximately 0.0001 microns. To put that in perspective:

- It is over 5000 times smaller than a bacterium (bacteria: 0.2-5 microns).

- It is over 200 times smaller than a virus (viruses: 0.02-0.4 microns).

- It is only about 1.5 times the diameter of a water molecule.

This means that besides water molecules and trace amounts of minerals, virtually all known dissolved contaminants—such as heavy metals (lead, arsenic), pesticides, viruses, and fluoride—are effectively blocked. This is the fundamental reason why AquaClarion RO systems can produce near-pure water and ensure drinking water safety.

3. Filtration Mechanism: More Than Just a Simple “Sieve”

RO separation is a combination of physical and chemical processes:

- Precise Sieving: Size exclusion physically blocks larger pollutant molecules.

- Charge Repulsion: The negatively charged membrane surface effectively repels dissolved ions in the water that also carry a negative charge (e.g., arsenate, nitrate).

- Solution-Diffusion: Water molecules preferentially dissolve into the membrane material and diffuse through rapidly.

By optimizing these mechanisms, AquaClarion RO membranes maintain stable water flow while efficiently removing contaminants.

4. The Key Driving Force: Why is Pressure Needed? How Much Pressure?

The RO process does not occur naturally; it requires external pressure to push water molecules against the osmotic pressure through the membrane.

- Standard Operating Pressure: For municipal tap water (TDS < 500 ppm), the ideal pressure range is 60-80 psi (4.0-5.5 bar). Within this range, AquaClarion RO systems achieve optimal salt rejection (>95%) and reasonable water production efficiency.

- Insufficient Pressure (< 40 psi): Leads to slow water production, increased wastewater, and reduced purification effectiveness. In this case, a dedicated RO booster pump is needed (integrated or optional on some AquaClarion models).

- Excessive Pressure (> 90 psi): Can damage the membrane element, requiring a pressure-reducing valve for protection.

5. AquaClarion’s Optimized Design and Maintenance Tips

To ensure the RO membrane works efficiently long-term, our systems feature:

- Pre-filtration Cartridges: PP sediment filters and activated carbon blocks protect the RO membrane from chlorine and particulate damage.

- Automatic Flush Function: Periodically flushes the membrane surface to reduce contaminant buildup and extend membrane life to 2-3 years.

- Optimized System Recovery Rate: Balances the wastewater ratio to conserve water while protecting the membrane.

Maintenance Advice: Please replace pre-filters regularly (every 6-12 months); they are the “guards” for the RO membrane. When water production drops noticeably or the TDS value rises, it’s time to check or replace the RO membrane (approximately every 24-36 months).

Conclusion: Technology Empowers Pure Drinking Water

The RO membrane is a marvel of engineering. Through its nano-scale precision structure, multiple separation mechanisms, and pressure-driven process, it efficiently separates contaminants from water. Understanding these principles helps you better trust and maintain your AquaClarion RO system, ensuring it continues to provide safe, pure drinking water for you and your family.