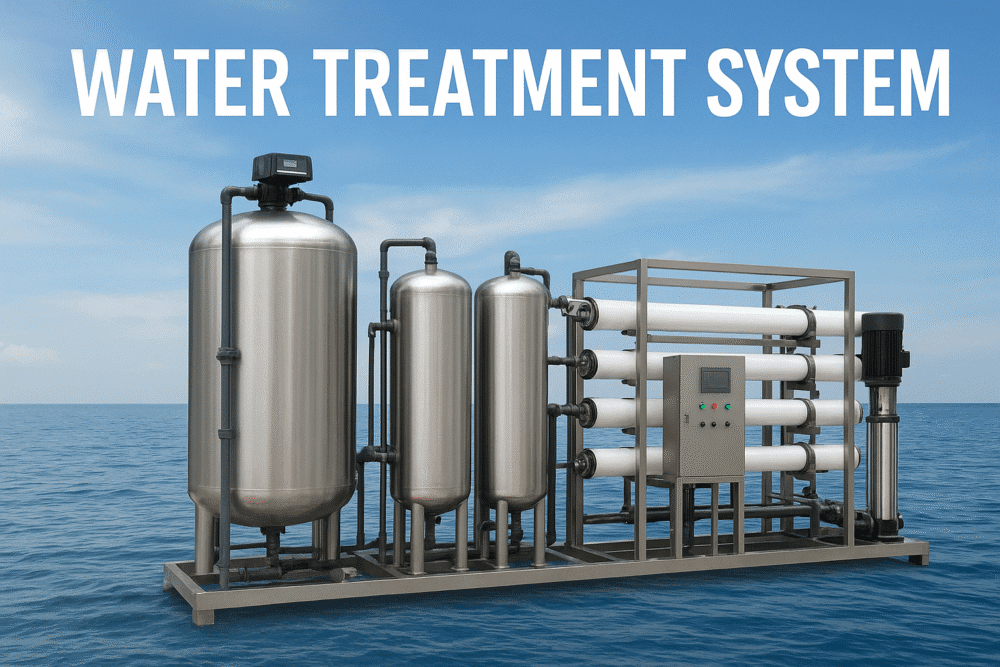

Water Treatment Systems have become essential across industrial, commercial, and residential sectors. With stricter global environmental standards and rising water safety awareness, more international buyers are looking for efficient, durable, and low-maintenance water treatment equipment.

This article provides a comprehensive overview of what water treatment systems are, how they work, their main categories, applications, and how to choose the right system for your project.

⭐ 1. What Is a Water Treatment System?

A water treatment system removes contaminants from water through physical, chemical, and biological processes. The goal is to improve water quality for drinking, industrial processing, wastewater discharge, or reuse.

Common contaminants removed include:

- Suspended solids and particles

- Organic pollutants (COD/BOD)

- Heavy metals

- Bacteria & viruses

- Unpleasant odors and color

- pH imbalance

⭐ 2. Main Types of Water Treatment Equipment

🔹 1. Pretreatment Systems

Used to remove large impurities and protect downstream equipment.

Typical equipment:

- Multimedia filters

- Quartz sand filters

- Activated carbon filters

- Cartridge filters

🔹 2. Membrane Filtration Systems

These are among the most popular high-precision filtration technologies.

Includes:

- RO (Reverse Osmosis) – removes 99% of dissolved salts, heavy metals

- UF (Ultrafiltration) – removes suspended solids, bacteria

- NF (Nanofiltration) – partial salt removal

- EDI – ultrapure water production

🔹 3. Disinfection Systems

Ensures microbiological safety.

- UV sterilizers

- Ozone generators

- Sodium hypochlorite dosing systems

🔹 4. Water Softening Systems

Removes calcium & magnesium ions to prevent scaling.

⭐ 3. Main Application Fields

Water treatment systems are widely used in:

- Industrial manufacturing (electronics, plating, chemical, textiles)

- Food & beverage production

- Municipal drinking water and sewage treatment

- Medical & laboratory water

- Hotels & commercial buildings

- Agriculture & aquaculture

⭐ 4. How to Choose the Right Water Treatment System?

Global buyers should focus on the following key factors:

✔ 1. Analyze the raw water quality

Different regions have different salinity, TDS, hardness, and pollutants.

✔ 2. Define your required water output standard

- Drinking water

- Ultrapure water

- Industrial process water

- Reclaimed wastewater

✔ 3. Evaluate core component brands

High-quality systems usually include:

- Membranes: DOW, Hydranautics

- Pumps: Grundfos, CNP,LEO,SHIMAGE

- Control systems: Siemens, Mitsubishi, PLC automation

✔ 4. Consider operation and maintenance cost

Energy consumption, membrane replacement, and waste-water ratio should be considered.

✔ 5. Ensure reliable technical support

Especially for overseas customers:

- Installation videos

- Technical manuals

- Remote troubleshooting

⭐ 5. Why More Global Buyers Choose Water Treatment Systems from China

Chinese manufacturers are becoming the preferred choice for international buyers because:

- Competitive pricing with high quality

- Fast lead time through large-scale manufacturing

- Flexible OEM/ODM customization

- Modern factories with strict quality control

- International certifications (CE, ISO, FDA)

⭐ Conclusion

As global environmental regulations continue to tighten, the demand for efficient water treatment systems will only grow. Choosing the right equipment will help companies reduce operating costs, improve production efficiency, and meet international environmental standards.