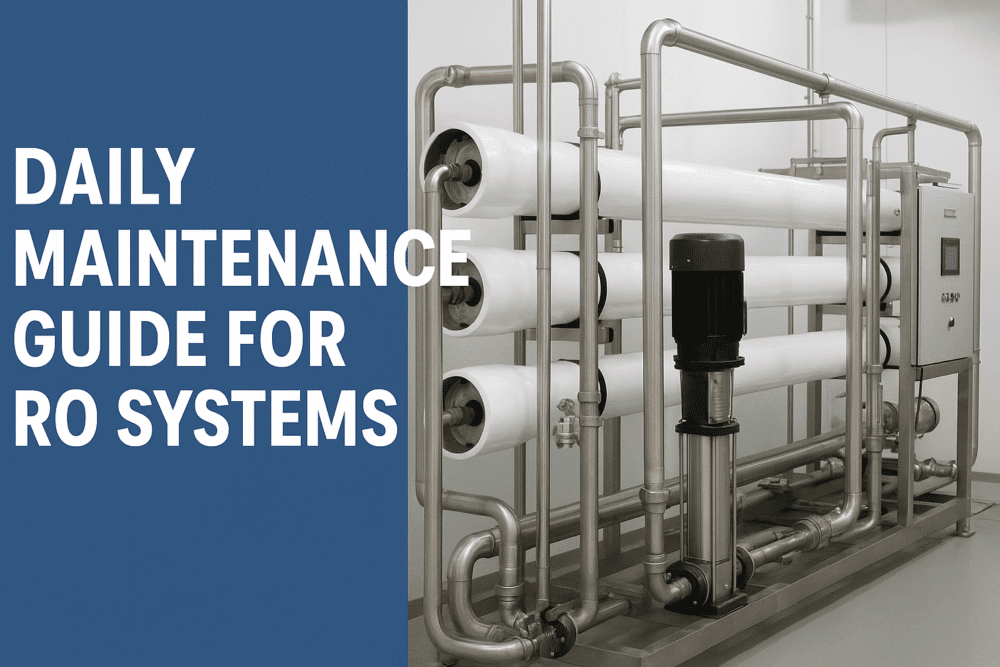

Reverse Osmosis (RO) water purification systems are widely used in industrial production, commercial facilities, and residential applications due to their reliable filtration performance and stable water quality. However, maintaining efficient system operation requires consistent daily maintenance.

This article provides a complete and professional daily maintenance guide to help you extend membrane life, reduce failures, and ensure long-term stable performance of your RO system.

1. Main Components of an RO Water Purification System

Understanding the structure of the system helps improve maintenance efficiency. A typical RO system includes:

- Pretreatment System (sand filter, activated carbon filter, water softener, cartridge filter)

- High-Pressure Pump

- RO Membrane Modules

- Pressure Gauges, Flow Meters, Conductivity Meters

- Piping and Valve System

- Electrical or PLC Control System

Each component plays a crucial role in ensuring the system produces high-quality purified water.

2. Daily Maintenance Tasks for RO Systems

1) Check Operating Parameters (Daily)

Monitor key indicators such as:

- Feed pressure & permeate pressure

- Product water flow & concentrate flow

- Temperature

- Conductivity / TDS

- Recovery rate

- Differential pressure (ΔP) across membrane vessels

Any abnormal changes should prompt immediate troubleshooting.

2) Maintain the Pretreatment System

Pretreatment is essential to protect RO membranes. Poor pretreatment is the No.1 cause of membrane fouling.

Important tasks include:

- Backwashing the quartz sand filter

- Regenerating the activated carbon filter

- Ensuring the water softener has sufficient salt for regeneration

- Maintaining stable feed water quality (turbidity, hardness, chlorine level)

- Keeping SDI ≤ 5

High-quality pretreatment can extend membrane life by 1–3 years.

3) RO Membrane Care and Protection

The RO membrane is the core component of the system.

(1) Maintain stable operating pressure and flow

Low pressure affects water production; high pressure may damage the membranes.

(2) Perform regular flushing and chemical cleaning

Including:

- Forward flushing

- Back flushing (for certain systems)

- Chemical cleaning (CIP) when necessary

CIP is recommended when:

- Permeate flow drops by 10–15%

- Salt rejection decreases by ≥ 5%

- Differential pressure increases by ≥ 15%

Timely cleaning prevents irreversible membrane fouling.

4) Maintain High-Pressure Pump & Electrical Components

- Check pump bearings, noise, and temperature

- Ensure motor current stays within standard range

- Review frequency inverter and control cabinet for alarms

- Inspect all pipelines for leakage, vibration, or abnormal pressure

Healthy pump operation directly contributes to overall system stability.

5) System Cleaning & Disinfection

Depending on water quality and industry requirements:

- Regular system disinfection (especially for food/beverage sectors)

- Cleaning internal pipelines

- Washing and sanitizing storage tanks

This helps prevent microbial contamination inside the system.

3. Recommended Maintenance Schedule

| Task | Daily | Weekly | Monthly | Quarterly | Annually |

|---|---|---|---|---|---|

| Parameter inspection | ✔ | ||||

| Pretreatment backwash | ✔ | ✔ | |||

| RO membrane flushing | ✔ | ✔ | ✔ | ||

| Pump & pipeline inspection | ✔ | ✔ | ✔ | ||

| System sanitization | ✔ | ✔ | ✔ | ||

| RO membrane chemical cleaning | ✔ | ✔ (if needed) |

4. Common Problems & Prevention Tips

1) Membrane Fouling

Causes:

- Particles, sand, suspended solids

- Organic fouling

- Microbial growth

- Scaling due to hardness ions

Solution: Strengthen pretreatment + timely CIP.

2) Drop in Permeate Flow

Possible reasons:

- Membrane fouling

- Insufficient pump pressure

- Low water temperature

- Flow meter blockage

3) High Conductivity (Low Salt Rejection)

Possible causes:

- Membrane damage

- Feed water quality fluctuations

- Unstable operating pressure

5. Tips to Extend RO System Lifespan

- Use high-quality filters and chemicals

- Avoid frequent start-stop cycles

- Apply membrane preservation procedures during long shutdowns

- Prevent overpressure operation

- Keep detailed operational logs

- Use real-time monitoring instruments

Proper maintenance can ensure RO systems operate efficiently for 5–8 years or longer.

Conclusion

Daily maintenance is essential to ensure stable performance and long service life of RO water purification systems. By following the recommended procedures and addressing abnormal conditions promptly, you can significantly lower operating costs and ensure consistent, high-quality water output.